Scientists prepare a new type of biodegradable electronic component that will be

Recently, in order to address the application challenges of biodegradable electronic devices, Associate Professor Zhang Qiuhong from Nanjing University and her team have developed a new type of controllable degradable material.

This material not only has excellent water resistance and biocompatibility but also has programmable mechanical properties, which can actively control the degradation rate, thus serving as a packaging material or substrate material for biodegradable electronic devices.

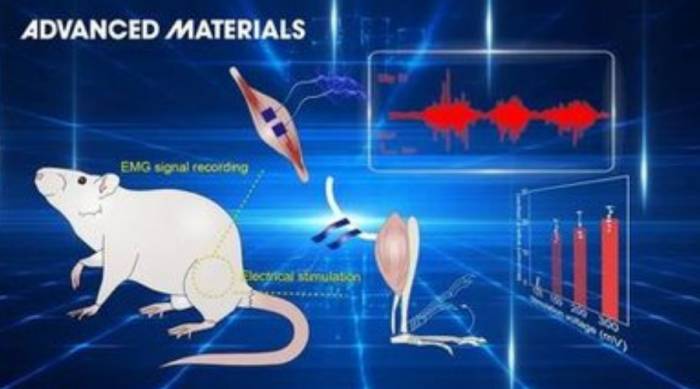

The bioelectronic devices prepared from this material can ensure normal and stable operation of the devices after being implanted in the body. In the later stage, the degradation rate can be artificially adjusted according to needs, thus accelerating degradation and absorption.

It is expected that this material can be used in the fields of medical patches, implantable medical beauty materials, implantable cartilage materials, controllable degradable bioelectronic substrates or packaging layers, and degradable self-powered systems.

Furthermore, based on this achievement, various biodegradable electronic devices can be developed, specifically:

(Note: The text was cut off, so the specific types of biodegradable electronic devices that can be developed are not provided.)Firstly, a "monitor" for bone repair that can actively regulate the rate of degradation can be developed.

When this "monitor" is implanted at the site of bone defect, it can not only monitor the rate of bone growth but also assess and reasonably regulate the degradation rate of the "monitor" based on feedback information, so as to accommodate the growth of the bone until it is completely repaired. At the same time, the "monitor" can also be completely degraded.

Secondly, a "monitor" for tumors that can actively regulate the rate of degradation can be developed.

After the tumor is removed, the "monitor" is implanted in the corresponding area. On the one hand, it can monitor whether there are residual tumor complexes after the operation.

On the other hand, the degradation rate of the "monitor" can be adjusted based on the feedback results, so as to better release anti-tumor drugs, play a role in inhibiting or killing tumor cells, until the tumor is completely eliminated, and the "monitor" can also be completely degraded.Thirdly, supercapacitors that can actively regulate the degradation rate can be developed.

Once these capacitors are implanted into the body, they can provide power to other electronic devices. After completing the designated tasks, by adjusting the degradation rate of the capacitor, it can be made to degrade as quickly as possible within the body.

Fourthly, blood flow sensors that can actively regulate the degradation rate can be developed.

Once these sensors are implanted into the body, they can monitor blood flow speed or pressure in real time, providing feedback on the progression of diseases to the outside world, and thus enabling the timely design of the best treatment plan.

After the patient has recovered, the degradation rate of the sensor can be artificially adjusted, allowing it to degrade as quickly as possible within the body.The translation of the provided text into English is as follows:

Both stable operation and complete degradation are required.

For many years, in order to better monitor, diagnose, and treat physiological signals and diseases within the human body in real time, researchers have developed various implantable bioelectronic devices.

For example, implantable blood glucose monitoring electronic devices, implantable degradable "electronic drugs," implantable neural microelectrodes, implantable triboelectric generators, implantable supercapacitors, etc.

Among them, biodegradable sensors, biodegradable supercapacitors, biodegradable triboelectric nanogenerators, and other biodegradable electronic devices can be directly degraded and absorbed after completing their designated tasks in the body, without the need for a second surgery. This can reduce the pain of patients and lower the cost of treatment.For such devices, they typically use biodegradable polymer materials such as polylactic acid (PLA), polycaprolactone (PCL), and poly(1,8-octanediol-co-citrate) (POC) as the encapsulation layer, and use biodegradable metals such as magnesium, zinc, and iron as internal wires and electronic components.

On one hand, these devices need to maintain stability during operation. Once the device is implanted in the body, extracellular fluids such as plasma and tissue fluid can easily penetrate the outer encapsulation layer, thereby entering the interior of the device, which may lead to corrosion of the metal wires or the device itself.

To address this, researchers use measures such as increasing the thickness of the encapsulation layer to suppress the infiltration of extracellular fluids, thereby resisting external forces and ensuring that the device has a sufficiently long working life.

On the other hand, the degradation of most biodegradable devices in the body requires a relatively long period, which undoubtedly poses some potential risks, such as inducing inflammatory responses, affecting the growth or repair of surrounding tissues/organs, etc.

Therefore, how to ensure that biodegradable electronic devices operate normally and stably during their working period, and can be safely, efficiently, and quickly degraded, is one of the challenges currently faced in this field. The key to solving this problem lies in the materials.Based on this, Zhang Qiuhong and her team carried out this series of studies.

The key lies in: how to encapsulate and prepare polymer materials for electronic devices. After research, they found a biodegradable elastomer: citrate-based polymer - poly(1,8-octanediol-co-citrate).

In 2020, the U.S. Food and Drug Administration (FDA) approved two orthopedic implant devices made from POC materials.

Later, the research group of Professor John A. Rogers at Northwestern University and Professor Bao Zhenan's research group at Stanford University, among other laboratories, began to use POC materials as the substrate and encapsulation for biodegradable electronic devices.

Taking this as a reference, Zhang Qiuhong's team also decided to choose POC as the base material. First, they characterized and analyzed the molecular structure, hydrophilicity, water absorption, and degradation reaction of POC, and studied the degradation behavior of POC in vitro and in vivo, finding that the degradation mechanism of POC comes from bulk erosion.The paper on this part of the research was published in Biomacromolecules in 2022 [1], and subsequently, this paper was cited by research groups from Yonsei University in South Korea, the University of Toronto in Canada, the Beijing University of Aeronautics and Astronautics, and other domestic and international research teams [2-4].

After completing the previous step, they began to introduce dynamic bonds into biodegradable elastomers. Based on the team's previous experience, they made the following conjecture: Why not introduce dynamic bonds into biodegradable elastomers and adjust the degradation rate effectively through the breaking of dynamic bonds?

So, they introduced dynamic disulfide bonds (S-S) into polyoxanorbornene (POC), using the mechanism of L-glutathione's reducing ability to break S-S bonds, and created a citrate-based polymer (POC-SS) that can actively control the degradation rate.

The POC-SS material has excellent mechanical properties and antibacterial properties, as well as good biocompatibility, and the degradation rate of the POC-SS material can be well controlled by glutathione.

In the experiment, no adverse reactions were observed in the animal model, and the paper on this part of the research was also published in Biomacromolecules [5].However, despite the characteristic of the POC-SS material that can actively regulate the degradation rate, its strong water absorption limits its application scope.

To address this, the team, based on the mechanism of the POC-SS material that can regulate the degradation rate, still used POC material as the base material, then introduced S-S for it, and based on the mechanism that glutathione can reduce the S-S bond and break it, the material has the characteristic of being able to actively regulate the degradation rate.

"You first convince me, then go convince the reviewers."

Considering that after electronic devices are implanted in the body, if accelerated degradation occurs, it may induce some inflammatory effects. Therefore, the research team introduced the bioactive molecule resveratrol (Res) into the POC cross-linked network.As a natural bioactive product, resveratrol has antioxidant, anti-inflammatory, anticancer, and cardiovascular protection effects. After its introduction, it can play a preventive role in the potential inflammatory response during the controlled degradation process.

In addition, the introduction of resveratrol can effectively improve the mechanical properties of materials. By using 1,6-hexamethylene diisocyanate to incorporate compounds containing S-S and resveratrol into POC materials, it can play a role in mechanical modification while also enhancing the water resistance of POC materials.

Through this, the research team also synthesized a new citrate-based polymer (POC-SS-Res). Compared with POC materials, POC-SS-Res has superior mechanical properties and extremely strong water resistance.

Moreover, its degradation rate can be actively controlled, and the toxicity of the degradation products produced is relatively low, showing good biocompatibility after implantation into animal models.

Subsequently, they encapsulated a simplified degradable electronic conductor (Mg coil) in both POC materials and POC-SS-Res materials, thereby creating two biodegradable electronic components (POC@Mg Coil and POC-SS-Res@Mg Coil).When two electronic components were simultaneously placed in polybutylene succinate (PBS) to simulate in vivo applications, the service life of the POC-SS-Res@Mg Coil was four times longer than that of the POC@Mg Coil, mainly due to the excellent hydrophobicity of POC-SS-Res.

Subsequently, they placed the used POC-SS-Res@Mg Coil in PBS to simulate in vivo degradation, and found that it could only undergo slow natural degradation.

This is also the degradation evolution process of current biodegradable electronic devices after completing their predetermined tasks in the body.

However, when they added glutathione, the degradation rate of the POC-SS-Res@Mg Coil began to increase rapidly, and the degradation cycle was significantly shortened.

Moreover, the degradation rate can be artificially adjusted according to the amount of glutathione used. This also means that they have successfully created an excellent new type of biomaterial, POC-SS-Res.In the research, Zhang Qiuhong and her students would also have debates over certain viewpoints, but instead, new ideas could be generated in the process of critical thinking.

Zhang Qiuhong said: "I have always strongly encouraged students to debate with me, and I often tell everyone 'convince me first, then convince the reviewers'. Fortunately, we can always reach a consensus in the end."

Ultimately, the related paper was published under the title "Tough and Water-Resistant Bioelastomers with Active-Controllable Degradation Rates" in ACS Applied Materials & Interfaces[6].

Wan Lu is the first author, and Zhang Qiuhong and Professor Jia Xudong from Nanjing University serve as co-corresponding authors.Utilizing Dynamic Keys for the Controllable Degradation of Bioelastic Materials

Of course, the preparation of controllable actively degradable elastic materials is only a small step in this series of studies, and there is still a long way to go before practical application.

At present, this material still relies on the injection of glutathione near the device to stimulate degradation, but the local concentration of glutathione cannot be effectively maintained. Therefore, they look forward to working with researchers in different fields to overcome the above-mentioned challenges, specifically:

On one hand, they will stimulate the local production of high concentrations of glutathione through cascade reactions or chemical biology methods, thereby achieving the controllable degradation of implanted materials through the oral or intravenous injection of small molecule drugs.

On the other hand, they will also functionalize such materials to achieve more processing and molding methods, such as 3D printing, and further expand the application of such materials in the fields of surgery, orthopedics, and medical aesthetics.It is worth noting that Zhang Qiuhong is a veteran "Nanda" person, having been here since studying at Nanjing University in 2003, and he has been here for 21 years. Even when studying in the United States, he went to the research group of Professor Bao Zhenan at Stanford University, and Bao Zhenan happens to be an alumnus of Nanjing University.

After working at Nanjing University for many years, Zhang Qiuhong not only met many good teachers and friends, but also deepened his love for playing table tennis. He said: "I met some friends in the education and academic circles through table tennis. When playing, sometimes some new ideas will be sparked inadvertently.

I also organize a table tennis friendship match for alumni and teachers and students of the Chemistry School of Nanjing University every year to promote communication among everyone." With achievements in work and pleasure in spirit, this is probably the best state for scientific researchers.

POST A COMMENT